In recent years, the movement towards eco-friendly alternatives to traditional plastics has gained significant traction. One such innovative solution is the production of corn starch bags, which offer a promising path towards reducing our reliance on non-biodegradable materials.

These eco-friendly bags are made from 100% biodegradable and compostable materials derived from plants, particularly corn starch. What’s unique about these bags is that they closely resemble conventional plastic bags in appearance and texture but are entirely environmentally friendly.

Let’s delve into the fascinating process of how corn starch bags are made.

Manufacturing Process of Corn Starch Bags:

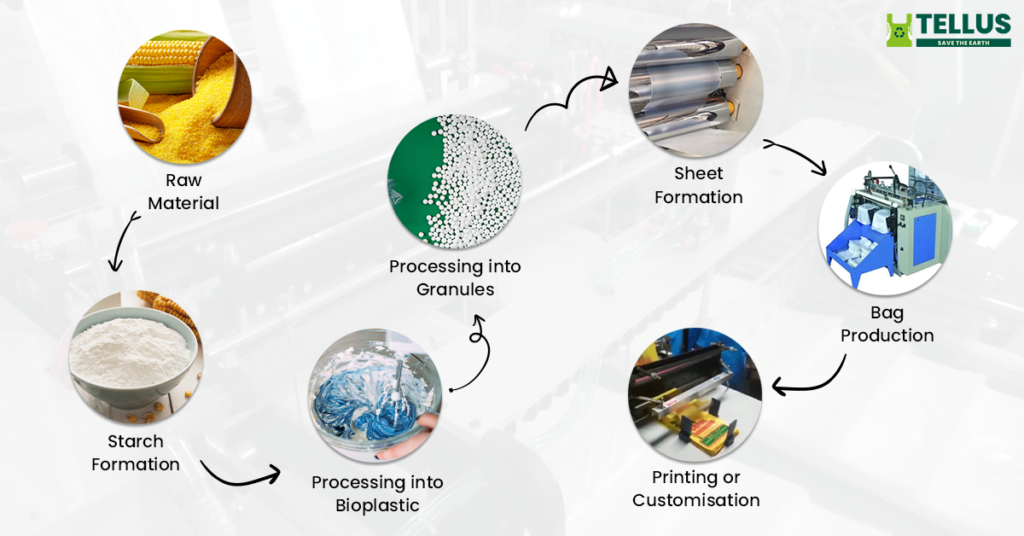

- Raw Material: The primary raw material used is starch, typically sourced from maize (corn). Corn Starch is chosen for its biodegradable properties and ease of processing.

- Processing into Bioplastic: To enhance the properties of corn starch for bag production, additives such as plasticizers and biodegradation agents are mixed into the corn starch. This step aims to improve flexibility and durability while ensuring eco-friendly decomposition.

- Processing into Granules: The starch is processed into granules or pellets, suitable for use in manufacturing. This step involves refining and drying the starch to create the desired texture and consistency for bag production.

- Sheet Formation: The granules are then fed into a blowing machine, where they are melted and extruded to form thin sheets of material. These sheets serve as the base for manufacturing carry bags.

- Bag Production: The sheets of starch-based material are cut and shaped into carry bags of various sizes and designs using specialized equipment. The manufacturing process is controlled by software that can adjust settings to produce bags of different qualities and thicknesses without the need for hardware modifications.

Final Customization for Branding : After the corn bags are carefully crafted and filled, the final step involves customization for branding. This is where the bags are personalized according to the client’s specifications. Customization options may include adding logos, slogans, or specific designs using printing techniques such as screen printing or embroidery. Branding not only enhances the aesthetic appeal of the corn bags but also promotes the client’s brand identity. This step adds a unique touch, making each bag a distinctive and impactful promotional item.

Benefits of Corn Starch Bags :-

Corn starch bags have many advantages for the environment:

- They break down naturally, so they don’t stay in landfills for a long time.

- Corn starch comes from renewable resources like corn, not from fossil fuels.

- Making corn starch bags usually produces fewer greenhouse gases than making plastic bags.

Conclusion:

The step-by-step process of making bags using corn starch highlights the innovative approach towards sustainable packaging solutions.

In the realm of eco-friendly packaging solutions, Tellus by BBMedicare stands as a pioneer. Based in Cuttack, Odisha. We are the biodegradable bag manufacturers in India. Specialize in manufacturing bio-compostable corn starch bags tailored to eco-conscious consumers and businesses. We offer a diverse range of bio-compostable bags, including grocery bags, carry bags, shopping bags, pharmacy bags and garbage bags, each available in different sizes, microns and capacities to cater to various needs.

Making bags from corn starch is a smart way to reduce plastic waste and protect our planet. By choosing corn starch bags, we can all make a positive impact on the environment. Let’s work together to create a cleaner, healthier world—one corn starch bag at a time!

By opting for corn starch bags, businesses and consumers contribute to a cleaner, greener future. Embracing eco-friendly alternatives is a crucial step in mitigating plastic pollution and preserving our planet for future generations.

Choose BBmedicare bio-compostable bags to help reduce plastic waste. Say no to plastic and embrace eco-friendly alternatives.